by Sven Krause | May 20, 2017 | ROTOCON, ROTOCON Case Study

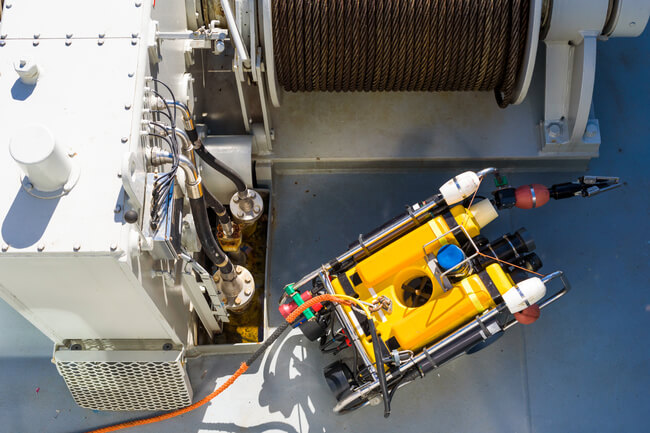

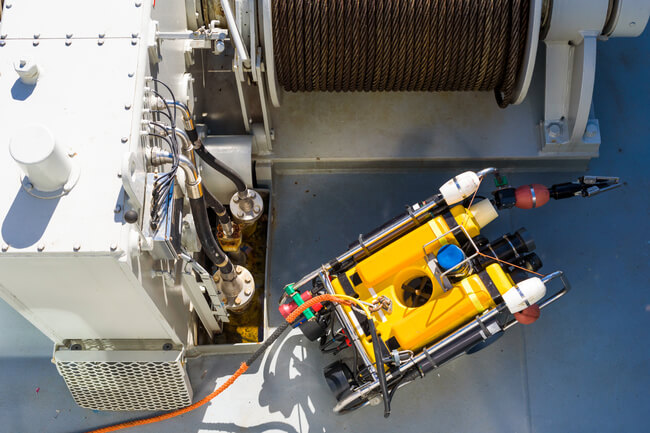

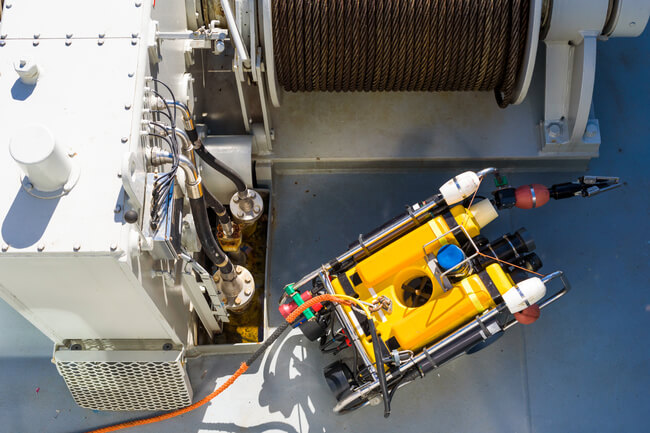

PROBLEM A manufacturer of oceanographic winches and test equipment contacted Meridian Laboratory about numerous issues with conventional slip rings used on its vessels’ deep-sea winch assemblies. Issues included noise generated by slip ring brushes, contact...

by Sven Krause | May 10, 2017 | ROTOCON, ROTOCON Case Study

PROBLEM A pioneer in the compressor and air conditioning and refrigeration systems industry approached Meridian Laboratory with challenges in rotary tank welding applications. The company’s manufacturing process included using conventional magnetic and screw-on,...

by Sven Krause | Apr 20, 2017 | ROTOCON, ROTOCON Case Study

PROBLEM A worldwide manufacturer of can, bottle and end-making machinery for the global can-making industry approached Meridian Laboratory with the concept of using high-speed photo/video to individually inspect cans, lids and other components in the manufacturing...

by Sven Krause | Mar 10, 2017 | ROTOCON Case Study

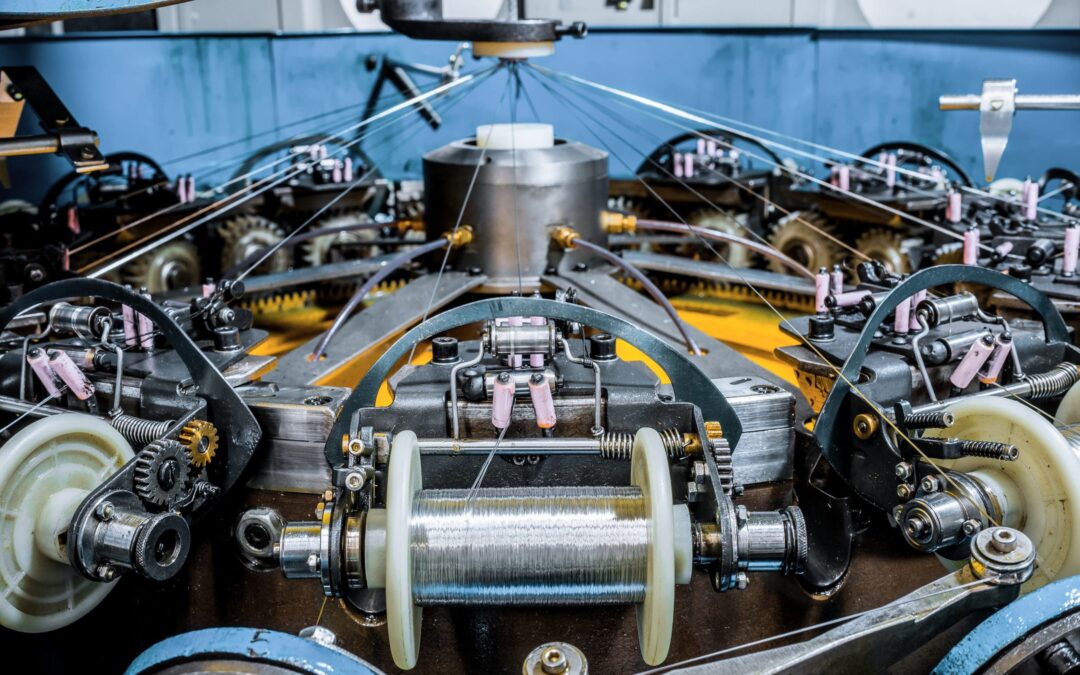

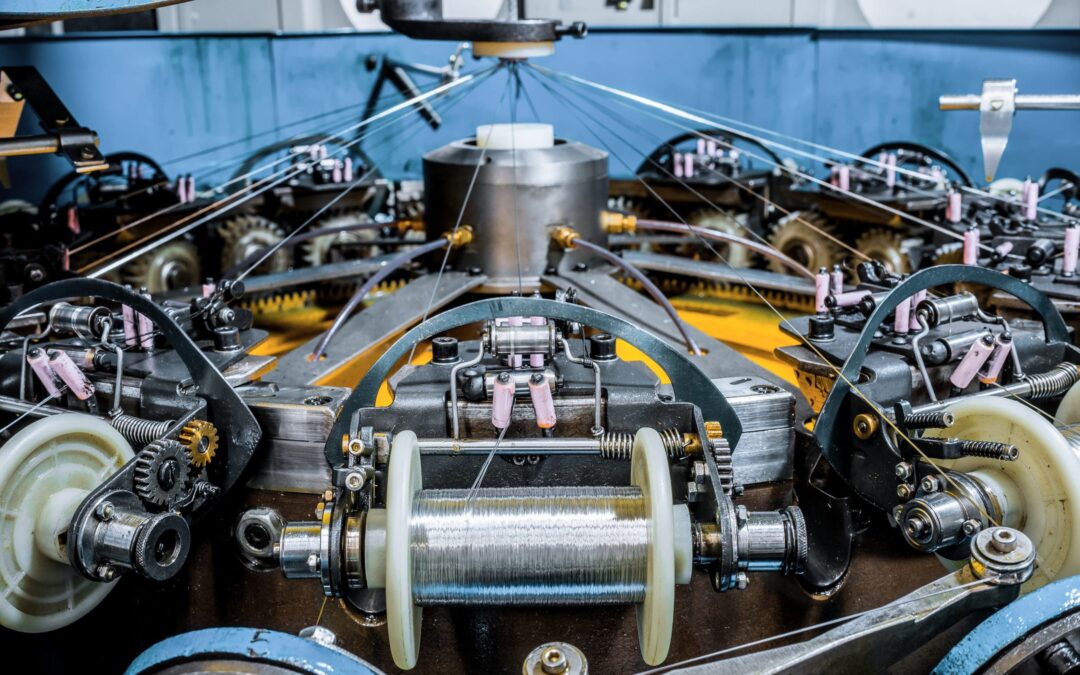

PROBLEM A leading manufacturer of fiber optic cable and fiber optic and copper cable hardware and equipment approached Meridian Laboratory to address issues with existing brush-style slip rings on its manufacturing equipment. While the conventional slip rings could...

Recent Comments