by Sven Krause | Jan 12, 2018 | ML6

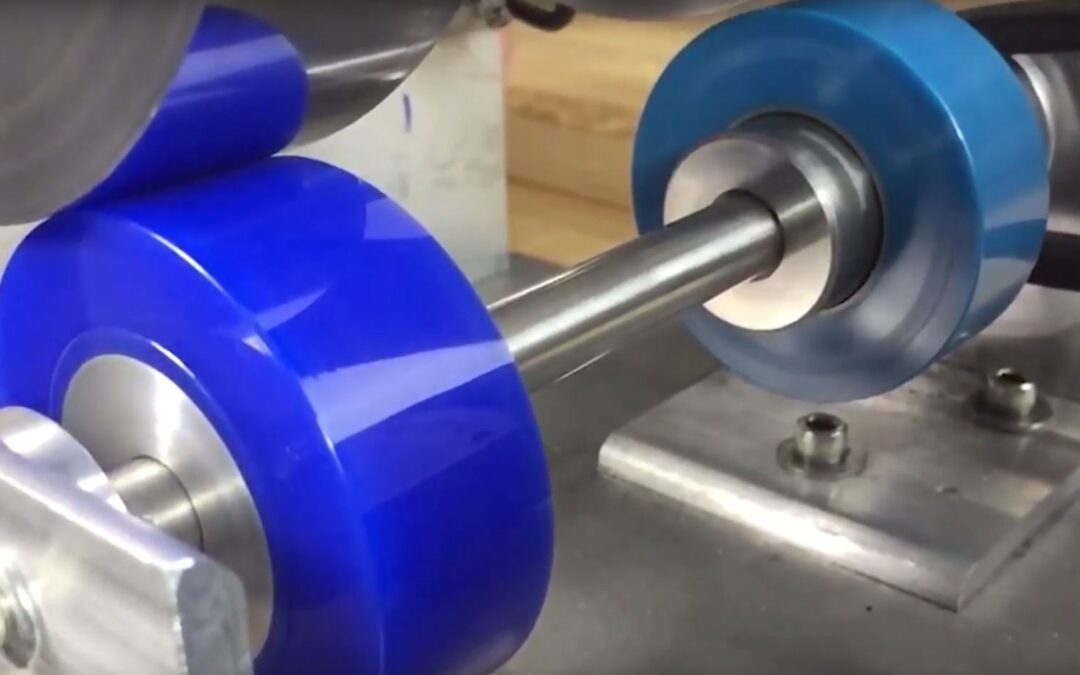

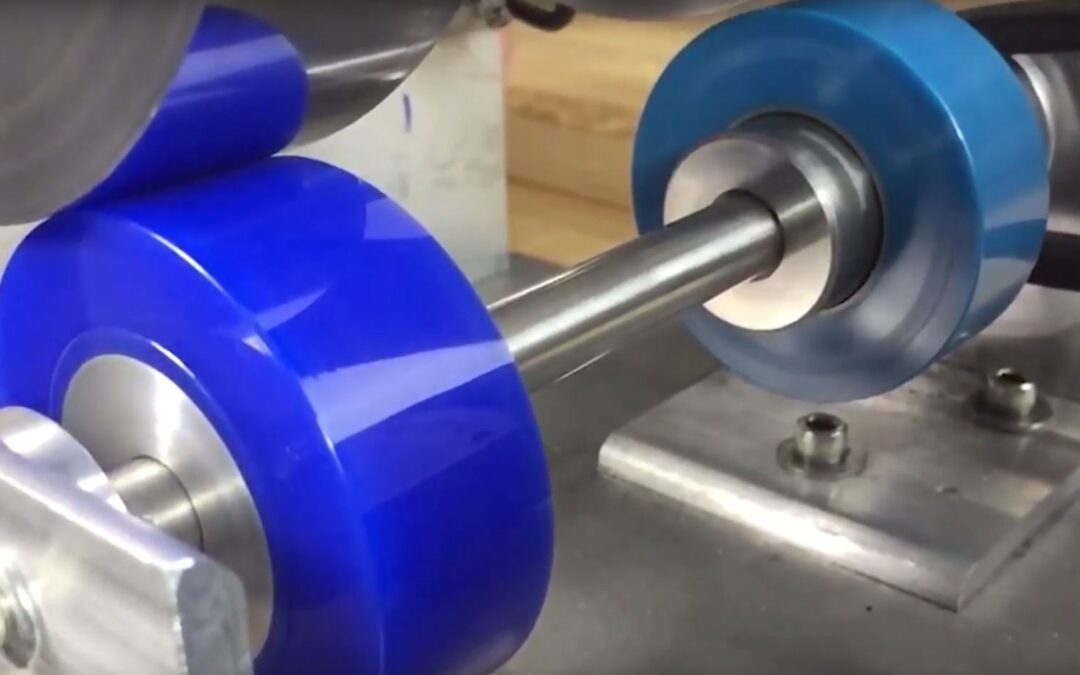

Having worked with raw base polymer manufacturers for more than 55 years, Meridian Laboratory has developed custom polyurethane ML6 blends, which are used in the manufacture of a roller that meets the design needs of many industries. Here are just a few reasons how...

by Sven Krause | Nov 8, 2017 | ML6

Here at Meridian Laboratory, we pride ourselves on our ability to create products of excellent quality and for our ML6 rollers, this obsession with quality extends to what is called total indicated runout or TIR. Total indicated runout is an important variable in...

by Sven Krause | Sep 27, 2017 | ML6

Innovation has become a business buzzword -everywhere you look some company is claiming they are the innovative, creative, thought leaders in their space. The only way to tell who the real innovators are is by seeing who was there first. To illustrate why Meridian...

by Sven Krause | Aug 4, 2017 | ML6

Each year, Meridian Laboratory works with dozens of engineers, designers, maintenance technicians, and machine builders to help them solve problems using Meridian Laboratory’s precision molded polyurethane ML6. While we oftentimes have standard, off-the-shelf...

by Sven Krause | Jul 26, 2017 | ML6, ML6 Case Study

The Problem In the manufacture of glass, consistent quality is everything. Any small imperfection in a pane can lead to fragility, haziness, granularity problems, or warping. The machines that are used to make these panes, such as glass handling and assembly...

by Sven Krause | Jun 19, 2017 | ML6, ML6 Case Study

PROBLEM The world’s largest manufacturer of manila envelopes and folders, contacted Meridian Laboratories due to numerous challenges they faced with multiple rollers on various models of machines. Aside from the fact that factory supplied machine ground rubber rollers...

Recent Comments