TECHNICAL FEATURES

1200 AMP ROTARY GROUND SERIES

- Rated to 1200 amps DC continuous at 100% duty cycle

- Offers consistent and stable current delivery and no fluctuation

- No maintenance and routine grease or brush replacement necessary

- Sensitive environment, non-mercury (RoHS) rotary grounds available

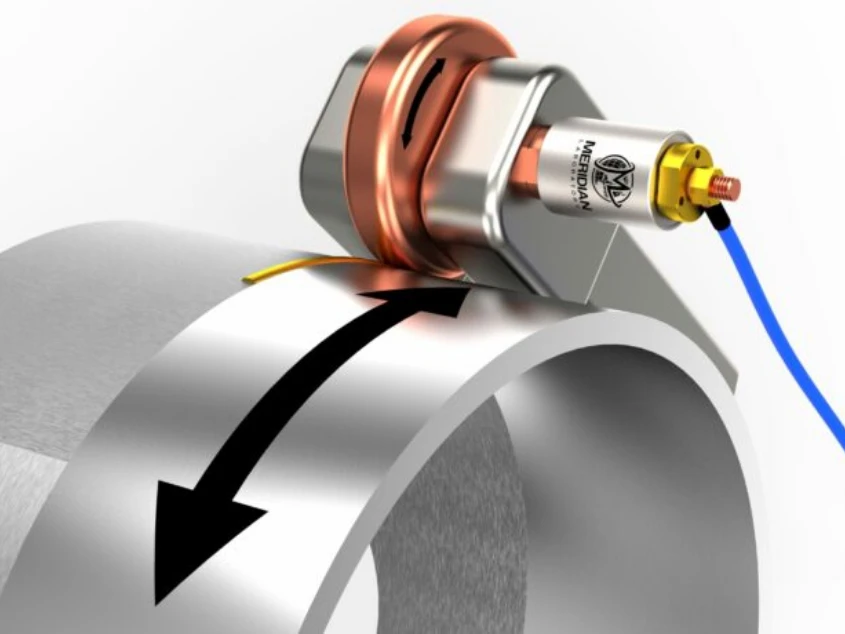

ROTOCON ERG-1200 rotary grounds are rated for 1200 amps continuous DC or AC up to 60 Hz, delivering stable, consistent current in high-power rotating applications without fluctuation. Meridian Laboratory brushless 1200 amp rotary grounds are designed as a superior alternative to traditional metal-on-metal rotary grounds, such as the Tweco (ESAB) Roto-Work models WCRG-1200 and WCRG-2000, ROTOCON ERG-1200 rotary grounds provides exceptional durability, performance, and reliability in demanding industrial environments.

Commonly used in rotary welding, electroplating, electropolishing, cutting, and other high-current applications, ROTOCON brushless ERG-1200 rotary grounds feature three different methods for easy integration across a wide range of applications. Unlike brushed and metal-on-metal rotary grounds, ROTOCON brushless 1200 amp rotary grounds are brushless and completely maintenance-free, eliminating the need for brush contact adjustments, grease application, or frequent replacements. Built for heavy-duty industrial use, ROTOCON brushless ERG-1200 rotary grounds are constructed from high-performance materials, ensuring long-lasting, trouble-free operation in the harshest conditions. Its arc-free design prevents internal arcing and degradation, making it the ideal choice for uninterrupted, high-power current transfer in the most critical applications.

Advantages

Why Choose ROTOCON 1200 Amp Rotary Grounds?

General Specifications

ERG-1200 Rotary Ground Specifications

AMPERAGE

1200

AMPS DC

Amperage refers to the continuously rated current specification of the product at direct current (DC) to low/common frequency levels (<120 Hz).For elevated current, temperature, or frequency applications - please contact Meridian Laboratory for more information.

CONTACT RESISTANCE

<0.03mΩ

Contact resistance refers to the electrical resistance between the stationary and rotating portions, internal to the ROTOCON rotating electrical connector. This is measured without additional cabling or connectors, and is internal to the units themselves. This is measured stationary or rotating, regardless of rotational direction, speed, or orientation.

DUTY CYCLE

100%

CONTINUOUS

Duty cycle refers to the duration of time at which the ROTOCON slip ring can operate within a maximum specified condition. Not all ROTOCON slip ring and rotary grounds are tested or guaranteed while in an absolute maximum condition of all specifications (rotational speed, amperage, etc.) simultaneously. For more information or application specific questions, please contact Meridian Laboratory.

Configurations

ERG-1200 Standard Models

| Name | Mounting | Amperage | Total Length | ROHS | RPM | Part Downloads | 2D Download Action Type | File Datasheet | Model Download (3D STP) | Photos |

|---|---|---|---|---|---|---|---|---|---|---|

| ERG-1200-01 | End of Shaft | 1200A | 4.5" | No | 000, 1 | Standard Model | MERIDIAN-LABORATORY-ROTOCON-ERG-1200-01.pdf | Yes | ||

| ERG-1200-01-R | End of Shaft | 1200A | 4.5" | Yes | 000, 1 | Standard Model | MERIDIAN-LABORATORY-ROTOCON-ERG-1200-01-R.pdf | Yes | ||

| ERG-1200-11 | End of Shaft | 1200A | 5.4" | No | 000, 1 | Standard Model | MERIDIAN-LABORATORY-ROTOCON-ERG-1200-11.pdf | Yes | IMG_0741_1.jpg | |

| ERG-1200-11-R | End of Shaft | 1200A | 5.4" | Yes | 000, 1 | Standard Model | MERIDIAN-LABORATORY-ROTOCON-ERG-1200-11-R.pdf | Yes | IMG_0741_1.jpg | |

| ERG-1200-21 | Flange | 1200A | 4.74" | No | 000, 1 | Standard Model | MERIDIAN-LABORATORY-ROTOCON-ERG-1200-21.pdf | Yes | ||

| ERG-1200-21-R | Flange | 1200A | 4.74" | Yes | 000, 1 | Standard Model | MERIDIAN-LABORATORY-ROTOCON-ERG-1200-21-R.pdf | Yes |

Mounting

1200 Amp Rotary Ground Mounting Options

ERG-1200-01

ERG-1200-11

ERG-1200-21

FAQs

Common Rotary Ground Questions

What size mount do I need?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat

Is this RoHS/CE compliant?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat

What speed does this reach?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat

How do I mount this item?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat

Customization

ERG-1200 Rotary Ground Customization Options

APPLICATIONS & USES

Common Uses for the ERG-1200

Rotary Welding & Cutting

Rotary grounds are essential for tanks, pipes, and other welding applications, providing a stable current transfer as materials rotate during welding. This ensures the seamless production of stacked tubes and other welded components. Likewise, welding tables, positioners, and robotic welding systems rely on a consistent electrical connection while the workpiece or welder moves, maintaining precision and efficiency throughout the welding process.

Rotational Plating & Polishing

When parts are placed into an electroplating or polishing bath, they are often rotated to ensure uniform coverage across all surfaces, leading to a higher-quality finish. Rotary grounds are essential to deliver a stable, consistent electrical current to the workpiece or fixturing during rotation.

Rotary Sputtering & Deposition

In sputtering applications, rotating electrical grounds create a reliable ground circuit for the rotating workpiece, ensuring even and consistent material deposition on the substrate. By maintaining stable ground resistance, the process can be more effectively controlled and monitored, leading to improved precision and a superior final product.

Resources

Helpful Information

Get the details you need—explore our complete resource library on every slip ring series.