OVERVIEW

Innovative, Maintenance-Free High Current Electrical Rotary Grounds

- PROVIDES STABLE AND CONSISTENT CURRENT

- DOES NOT REQUIRE GREASE, ADJUSTMENT, OR MAINTENANCE

- UNAFFECTED BY TOTAL NUMBER OF REVOLUTIONS OR ROTATION

- STANDARD MODELS AND CUSTOM SOLUTIONS

- NON-MERCURY ROTARY GROUND (RoHS) MODELS AVAILABLE

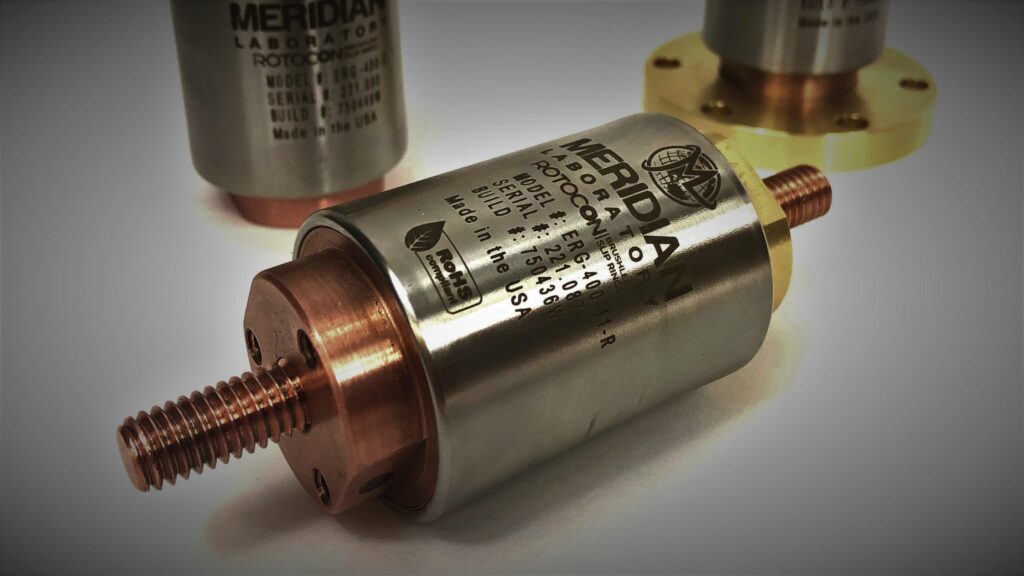

Meridian Laboratory’s ROTOCON ERG Series of brushless rotary grounds are designed to mount at the end of a workpiece and provide a low resistance rotating ground path. ROTOCON brushless rotary grounds provide stable and consistent current delivery with no changes or fluctuation in amperage over time regardless of orientation, total revolutions, or instantaneous speed.

All ROTOCON brushless rotating grounds are environmentally sealed and use robust and corrosion resistant materials that ensure a long service life without the maintenance and grease required by conventional, metal-on-metal rotary ground manufacturers such as Tweco (ESAB) Roto-Ground, Lenco, Sumner, and others.

ROTOCON brushless rotating grounds are widely used in rotary welding cells, rotary plating processes, and other high current applications which require a rotary ground. Although referred to as a rotary ground, these can be used for both power (positive) and return (ground) circuits with no impact on performance or lifespan.

ROTOCON brushless electrical rotary grounds are also offered in non-mercury, RoHS versions. Additionally, Meridian Laboratory can design and deliver Custom ROTOCON Rotary Grounds to meet your exact specifications in a cost and time efficient manner.

Advantages

Why Choose ROTOCON Brushless Rotary Grounds?

READY TO ELEVATE YOUR EXPERIENCE?

Explore the possibilities and configure your ideal solution with Rotocon's Product Configurator. Tailor your product to your unique needs in just a few clicks!

CONFIGURE YOUR ROTOCON

APPLICATIONS & USES

Common Uses for Rotary Grounds

ROTARY WELDING

ROTOCON rotary welding grounds are used in rotary welding applications which rotate the workpiece. This includes pipe, tube, and metal structure manufacturing processes. They eliminate tangled cables and provide consistent current without blow through or poor penetration.

ROTARY PLATING & DEPOSITION

ROTOCON rotary grounds are frequently used in rotational plating operations which demand stable current to ensure consistency throughout the entire process. They are sealed and built with corrosion resistant materials to withstand the harsh environments.

ROTARY CUTTING

ROTOCON rotary grounds are commonly used for rotary cutting applications and provide stable current flow for plasma cutting in fully or semi-automated applications. They provide a maintenance-free rotary ground to ensure maximum efficiency without downtime.

EXPLORE MORE

Related Articles for Rotary Grounds

Introducing the ERG-3000 Rotary Ground: Meridian Laboratory’s Latest Innovation for High Current Rotary Applications

Read MoreIntroducing the Innovative ROTOCON ERGT-800-1PRU Rotary Electrical Ground & Rotary Union Assembly by Meridian Laboratory

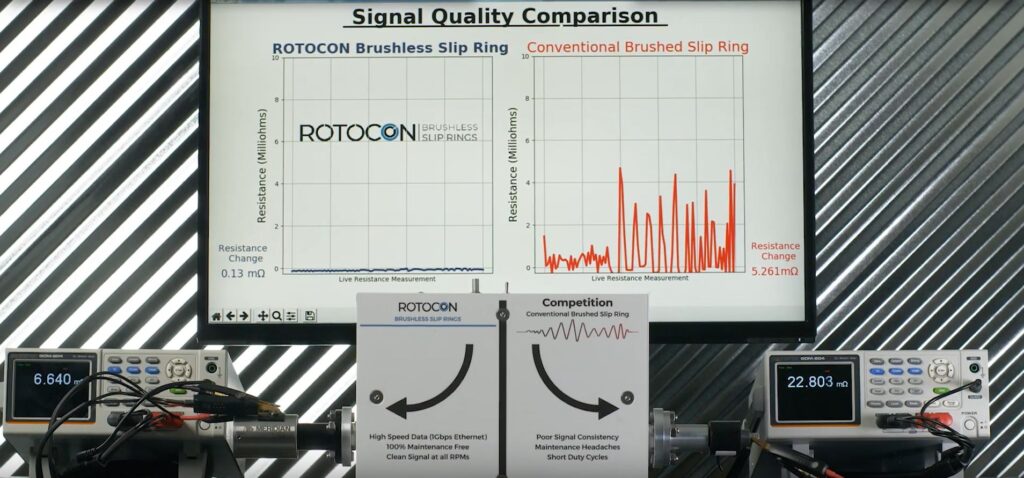

Read MoreJust how bad is your rotary ground performing? A head-to-head comparison of rotating electrical grounds.

Read MoreResources

Helpful Information

Get the details you need—explore our complete resource library on every slip ring series.