OVERVIEW

Through-Hole Slip Rings Designed for Shaft Mounting and Media Pass Through

- Up to 32 contacts available with up to 2” diameter through-hole (standard), up to 4" diameter (custom)

- Designed for over-shaft mounting for media / power to pass through the center hole

- Capable of power and data in one assembly

ROTOCON brushless through-hole slip rings are designed for applications which require a shaft or media to pass through the center of a slip ring. Through-hole slip rings are commonly used when a solid shaft is being used as a drive for rotating torque, or when a medium such as air, water or gas are passed through the center of a system.

ROTOCON brushless through-hole slip rings are offered in standard bore sizes up to 2.0” diameter, and custom sizes up to 4.0”. They are often used on rotary indexing tables, packaging and filling equipment, and other applications which require a hollow shaft slip ring.

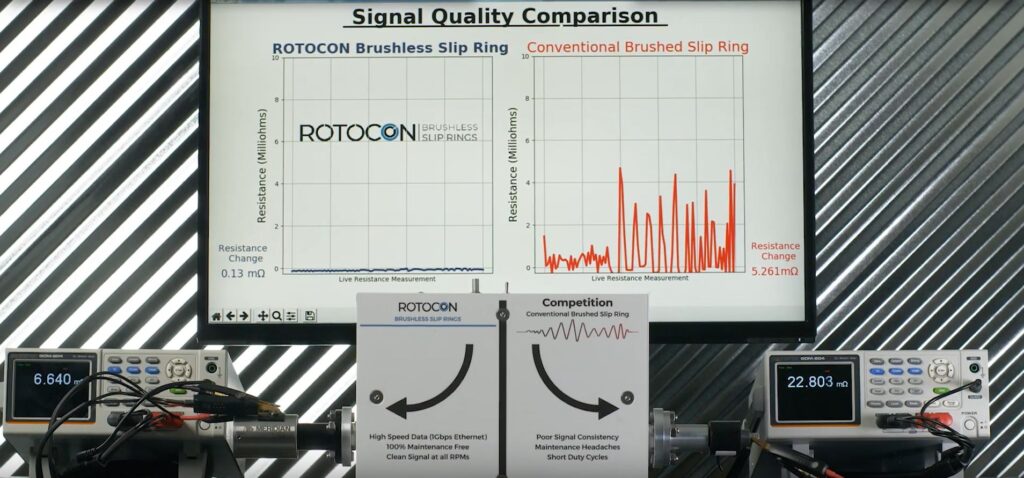

ROTOCON brushless through-hole slip rings are maintenance-free and commonly used in applications such as rotary indexing tables, packaging and filling equipment, semiconductor manufacturing, instrumentation, and various industrial and scientific settings. They deliver clean electrical power and signals with no measurable electrical noise, remaining unaffected by machine vibration, rotational speed, or total revolutions.

Designed for durability, all ROTOCON brushless through-hole slip rings are environmentally sealed and made from robust materials, making them the ideal solution for manufacturing, R&D, and high-performance applications. Their strong industrial design ensures reliable, long-lasting operation without the downtime or routine maintenance required by traditional brushed slip rings.

Meridian Laboratory offers the value-add capability of integrating with rotary unions and fiber optic rotary joints in a single combined assembly. For applications which have mounting access at the end of the shaft, please see our complete line of End-of-shaft, multi-channel slip rings.

Advantages

Why choose ROTOCON Brushless Through-Hole Slip Rings?

READY TO ELEVATE YOUR EXPERIENCE?

Explore the possibilities and configure your ideal solution with Rotocon's Product Configurator. Tailor your product to your unique needs in just a few clicks!

CONFIGURE YOUR ROTOCON

Applications & Uses

Common Uses for Through-Hole Slip Rings

ROTARY PACKAGING & FILLING

ROTOCON through-hole slip rings are used on rotational packaging and filling machinery in combination with rotary unions to fill sealed beverages and containers. They excel in continuous-duty applications where downtime is costly.

ROTARY INDEXING TABLES

ROTOCON through-hole slip rings are commonly mounted on indexing tables where the drive motor is center mounted, while passing power and Ethernet to devices and sensors on the top of the rotary table.

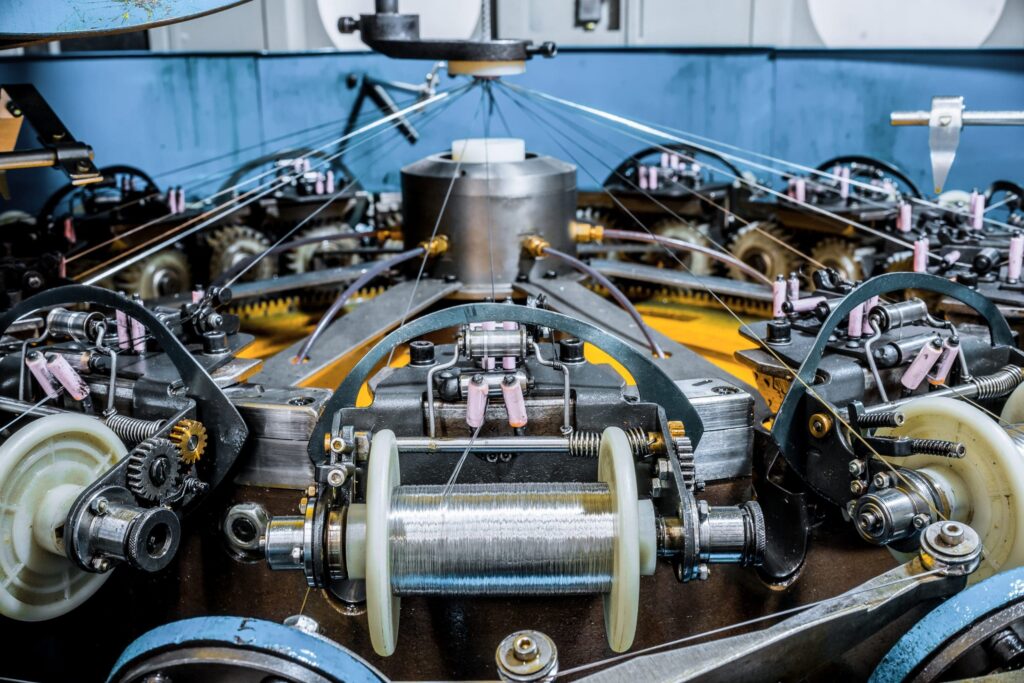

CABLE & WIRE BUNDLING MACHINES

ROTOCON through-hole slip rings can be utilized in wire manufacturing and cable bundling equipment which allows for materials to pass through the center. They provide stable and consistent electrical contact to motors, drives, and sensors while rotating.

EXPLORE MORE

Related Articles for Through-Hole Slip Rings

Resources

Helpful Information

Get the details you need—explore our complete resource library on every slip ring series.