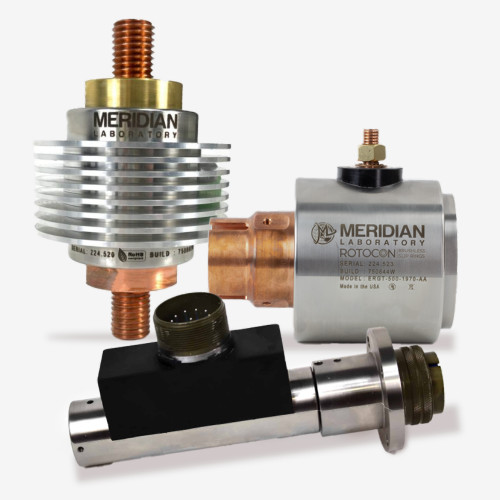

Brushless Electrical Slip Rings & Rotary Connectors

Standard and Custom Rotary Solutions

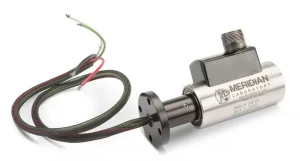

Meridian Laboratory’s ROTOCON brushless slip ring and rotating electrical connector technology provides an innovative alternative to traditional brushed electrical slip rings. With a wide range of standard models that can be easily configured to meet diverse application needs, we also specialize in custom-engineered rotating solutions, from prototype development to full-scale production. Our commitment is to deliver high-quality rotating electrical slip rings and rotary solutions to machine builders, OEMs, end-users, and R&D professionals worldwide.

Design Your Perfect ROTOCON Slip Ring

Use our comprehensive configurator to find or design the perfect brushless slip ring with ease!

Configure Your Part

RESOURCES

Helpful Information

Get the details you need—explore our complete resource library on every slip ring series.