Overview

ROTOCON Ultra High-Speed Slip Rings provide Clean & Stable Signals at Speeds Up to 40K RPM

- Offered in 1, 4, 8, and 12 electrical channel configurations.

- Capable of rotational speeds of up to 40,000 RPM without any measurable electrical noise

- Brushless contact features no wear points and does not require maintenance or adjustment over time.

ROTOCON ultra high-speed slip rings are ideal for applications with demanding operating speeds between 10,000 and 40,000 RPM. The ROTOCON UHS Series of ultra high-speed slip rings is offered in standard configurations up to 12 electrical channels, capable of providing up to 500 milliamps per contact.

ROTOCON ultra high-speed slip rings remain unaffected by rotational speeds and provide a low and stable electrical connection between stationary and rotating equipment. They are capable of providing excellent signal integrity for measurement devices including stress / strain gauges, torque, temperature, displacement, pressure, vibration, acceleration, oscillation, shock, force, and more.

ROTOCON ultra high-speed slip rings are commonly used for testing and validation of high-speed equipment such as electric motors, turbocompressors, propellers, electric motors, powertrain systems, and machine tools.

For applications which operate at lower speeds (less than 10,000 RPM), please see our MM Series of high-speed ROTOCON brushless slip rings.

Advantages

Why choose ROTOCON Ultra High-Speed Slip Rings?

General Specifications

Ultra High-Speed Slip Ring Specifications

MOUNTING

END OF SHAFT

All UHS Series ultra high-speed slip rings and rotary electrical connectors assume mechanical attachment at the end of the device under test (DUT); through-hole versions are not available in this series.

AMPERAGE

500mA (0.5A) / channel

Amperage refers to the continuously rated current specification of the product at direct current (DC) to low/common frequency levels (<120 Hz). For elevated current, temperature, or frequency applications - please contact Meridian Laboratory for more information.

VOLTAGE

60V

Voltage rating between two cells / wires, or between cells and housing/body. For higher voltage requirements, please contact Meridian Laboratory.

TEMPERATURE

-13°F to 140°F

Temperature rating is measured at the body of the ROTOCON slip ring under maximum current load and rotational speed; should not exceed 140˚F for continuous periods of time. For application specific scenarios, please contact Meridian Laboratory.

Design Your Perfect Custom ROTOCON Rotary Ground

Use our comprehensive configurator to find or design the perfect brushless rotary ground with ease!

Configure Your Part

Configurations

UHS Series Standard Models

| Name | MT - Max Operating Speed | Amperage | Mounting | Shaft Termination | Body Termination | Photos |

|---|---|---|---|---|---|---|

| UHS-201-011 | 20000 | 0.3A | End of Shaft | Solder Termination | Solder Termination | |

| UHS-201-111 | 40000 | 0.3A | End of Shaft | Flying Leads | Flying Leads | |

| UHS-201-111-F | 40000 | 0.3A | Flange | Flange | Solder Termination | |

| UHS-204-011 | 20000 | 0.3A | End of Shaft | Flying Leads | Flying Leads | |

| UHS-208-011 | 20000 | 0.3A | End of Shaft | Flying Leads | Flying Leads | https://drive.google.com/file/d/15pEOf9A6dVFlwwT5xMOeqDWvl2YLu5hq/view?usp=sharing |

| UHS-208-111 | 40000 | 0.3A | End of Shaft | Flying Leads | Flying Leads | |

| UHS-208-111 | 000, 40 | 0.3A | End of Shaft | Flying Leads | Flying Leads | |

| UHS-212-011 | 20000 | 0.3A | End of Shaft | Flying Leads | Flying Leads | |

| UHS-212-011 | 000, 20 | 0.3A | End of Shaft | Flying Leads | Flying Leads | |

| UHS-212-111 | 40000 | 0.3A | End of Shaft | Flying Leads | Flying Leads | |

| UHS-212-111 | 000, 40 | 0.3A | End of Shaft | Flying Leads | Flying Leads |

FAQs

Common Ultra High-Speed Slip Ring Questions

How is the UHS-series mounted?

The UHS series is mounted by holding the stationary portion of the device in a fixed position, and then using a flexible coupling to allow for slight misalignments in the system. For mounting accessories or more information, contact us directly to discuss your project.

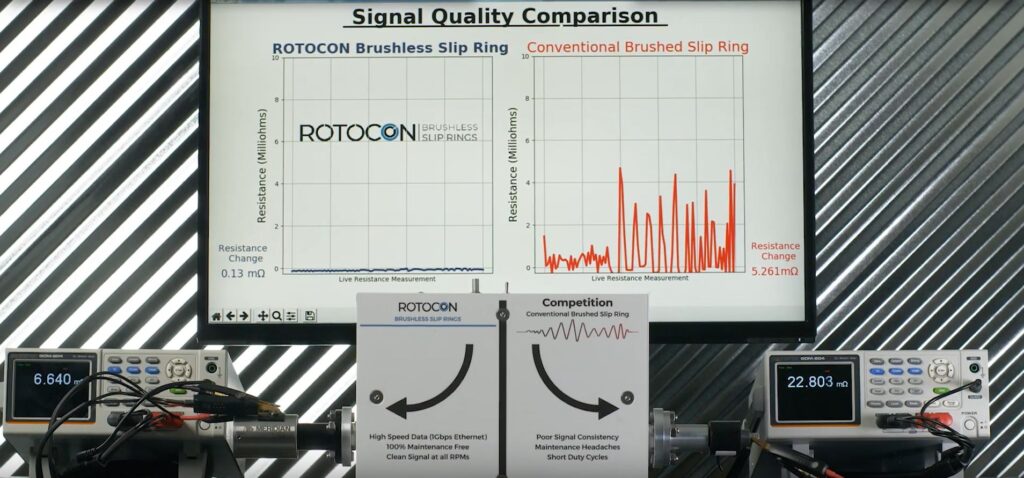

What is the resistance or noise generated under rotation?

From stationary to the rated maximum speeds, the electrical resistance and noise remains low and stable. The measurable results are typically 0.2mΩ (milliohm) resistance and 25µV/V under all speeds of rotation.

What types of signals and sensors are compatible with the UHS-series?

From stationary to the rated maximum speeds, the electrical resistance and noise remains low and stable. The measurable results are typically 0.2mΩ (milliohm) resistance and 25µV/V under all speeds of rotation.

Are they serviceable?

Yes, depending on the type of service required, Meridian Laboratory can provide testing, analysis and repair. HERE is a link to our RMA form to begin that process.

APPLICATIONS & USES

Common Uses for Ultra High-Speed Slip Rings

POWERTRAIN TESTING SYSTEMS

ROTOCON ultra high-speed slip rings and rotary electrical connectors are commonly used to measure vibration, torque, and other signals on electric motor drive systems and other vehicle components.

LUBRICATION & BEARING ANALYSIS

ROTOCON ultra high-speed slip rings are utilized to measure temperature, strain/stress, and other critical aspects of bearings and lubricants under rotation.

TURBO-COMPRESSOR TESTING

ROTOCON ultra high-speed rotating electrical connectors are utilized to measure signal measurements in live time from turbo compressors under rotation, reliably and consistently.

EXPLORE MORE

Related Articles for Ultra High-Speed Slip Rings

Resources

Helpful Information

Get the details you need—explore our complete resource library on every slip ring series.