Overview

Explosion Proof Slip Rings for Hazardous Locations – Certified, Reliable, and Customizable

- Certified for Hazardous Locations – IEC Ex db IIC T6 Gb and ATEX Ex II 2 G compliance for safe use in explosive gas and vapor environments

- High Performance – Supports 2 to 30 electrical channels, up to 3,000V, and speeds up to 500 RPM

- Flexible Mounting Options – End-of-shaft configuration available with or without a junction box to fit your application needs

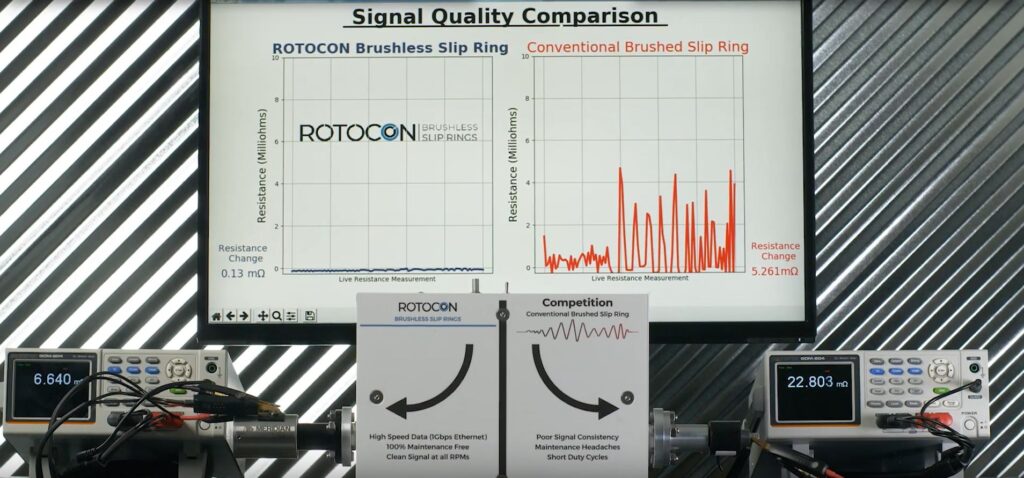

- Maintenance-Free, Arc-Free Design – Utilizes proven ROTOCON® brushless technology for reliable, long-lasting performance in critical environments

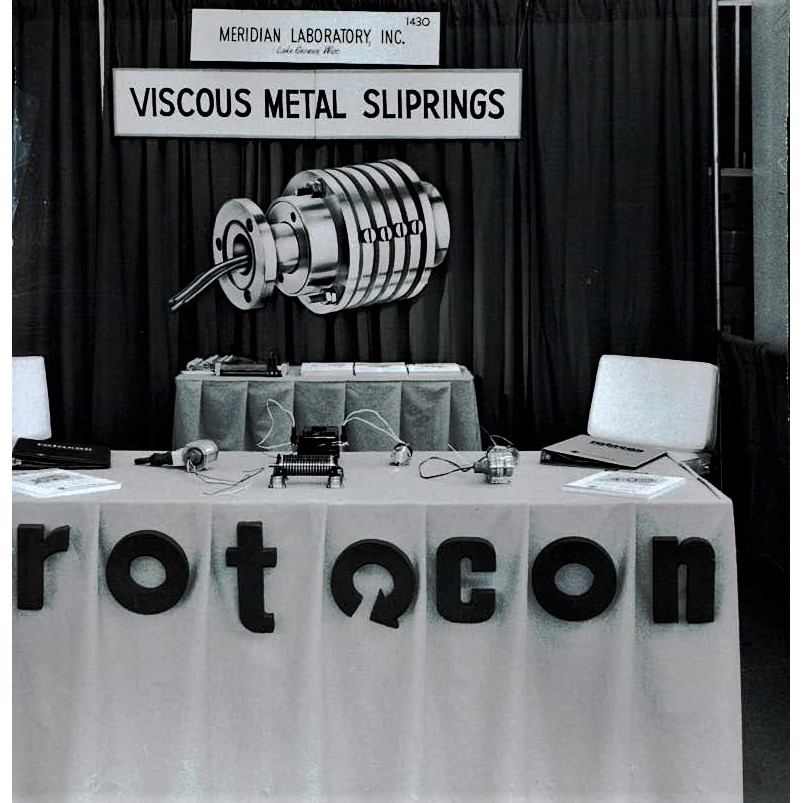

Meridian Laboratory’s HLMX series of Explosion Proof Slip Rings are engineered for safe and reliable operation in hazardous environments where flammable gases or vapors may be present. Certified to meet IEC Ex db IIC T6 Gb and ATEX Ex II 2 G standards, ROTOCON hazardous location slip rings are designed for use in demanding applications requiring robust explosion protection.

Our explosion-proof slip rings are designed for end-of-shaft mounting and are available with or without an integrated junction box, providing flexible installation options to suit your specific needs. The ROTOCON HLMX series can be configured with 2 to 30 electrical channels, supporting voltages up to 3,000V and rotation speeds up to 500 RPM.

Backed by Meridian Laboratory’s proven ROTOCON® brushless slip ring technology, our slip rings offer maintenance-free, arc-free performance, ensuring long-term durability and safety in ATEX/IECEx classified areas.

Advantages

Why Choose ROTOCON Hazardous Location Slip Rings?

General Specifications

Hazardous Location Slip Ring Specifications

Certification

IEC Ex db IIC T6 Gb

and ATEX Ex II 2 G

For other certifications, please contact Meridian Laboratory to discuss your application.

MOUNTING

End-of-Shaft

A selection of mounting flanges are available, with the option of Meridian Laboratory providing a custom-sized mounting flange to meet application-specific requirements.

RPM

Up to 1000 RPM

The maximum rotational speed of a ROTOCON washdown rotating electrical connector is directly limited to the temperature the slip ring reaches under maximum current load and rotational speed within a given environment. The speeds shown are up to and not guaranteed in absolute maximums.

TEMPERATURE

-35˚F to 160˚F

Temperature rating is measured at the body of the ROTOCON slip ring under maximum current load and rotational speed should not exceed 160˚F for continuous periods of time. For application specific scenarios, please contact Meridian Laboratory.

Design Your Perfect Custom ROTOCON Rotary Ground

Use our comprehensive configurator to find or design the perfect brushless rotary ground with ease!

Configure Your Part

Configurations

Hazardous Location & Explosion Proof Slip Rings

| Name | Channels | Amperage | Voltage | Data Capable | Terminations Available |

|---|---|---|---|---|---|

| Custom Hazardous Location ROTOCON Slip Ring | Up to 30 Channels | Up to 18A per Channel | 500V, up to 3 | Available up to 1000 Mbps (1 Gbps) Speed | or junction box, potted flying leads, Ring terminals |

| HLMX-12 | 12 | 18A | 500V (custom), 600V (standard), up to 3 | Yes | or junction box, potted flying leads, Ring terminals |

| HLMX-15 | 15 | 10A | 500V (custom), 600V (standard), up to 3 | Yes | or junction box, potted flying leads, Ring terminals |

| HLMX-2 | 2 | 18A | 500V (custom), 600V (standard), up to 3 | Yes | or junction box, potted flying leads, Ring terminals |

| HLMX-2 | 2 | 18A | 500V (custom), 600V (standard), up to 3 | Yes | or junction box, potted flying leads, Ring terminals |

| HLMX-20 | 20 | 10A | 500V (custom), 600V (standard), up to 3 | Yes | or junction box, potted flying leads, Ring terminals |

| HLMX-24 | 24 | 5.5A | 500V (custom), 600V (standard), up to 3 | Yes | or junction box, potted flying leads, Ring terminals |

| HLMX-30 | 30 | 4A | 500V (custom), 600V (standard), up to 3 | Yes | or junction box, potted flying leads, Ring terminals |

| HLMX-4 | 4 | 18A | 500V (custom), 600V (standard), up to 3 | Yes | or junction box, potted flying leads, Ring terminals |

| HLMX-8 | 8 | 18A | 500V (custom), 600V (standard), up to 3 | Yes | or junction box, potted flying leads, Ring terminals |

FAQs

Common Hazardous Location Slip Ring Questions

Can I specify an exact hole diameter?

Yes, while standard bore sizes are listed in the model chart, we can also provide rotary grounds to the exact bore diameter to fit your application.

Do you offer a rotary ground with a rotary gas/fluid union already integrated?

Yes, standard models include our ERGT-800-1PRU, however we can also integrate our rotary grounds to a variety of standard and custom rotary unions.

Which section of the rotary ground is electrically “live”?

The entire rotary ground is electrically “live” meaning there is no electrical insulation between the shaft and the body of the unit. Electrical current is designed to follow the path of least resistance internally between the shaft and conductive terminal stud.

Does conductive grease need to be used between the shaft being grounded and the ROTOCON rotary ground?

No, we do not recommend any grease between the shaft and the rotary ground. The shaft should be clean and free of grease and any debris that could compromise the electrical connection to the rotary ground. Click here for more information relative to mounting and use of the ERGT Series.

Customization

Hazardous Location & Explosion Proof Slip Ring Options

APPLICATIONS & USES

Common Uses for Hazardous Location Slip Rings

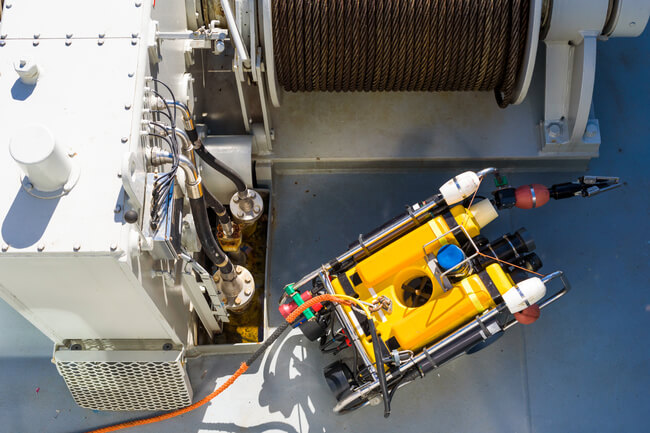

Oil & Gas Exploration

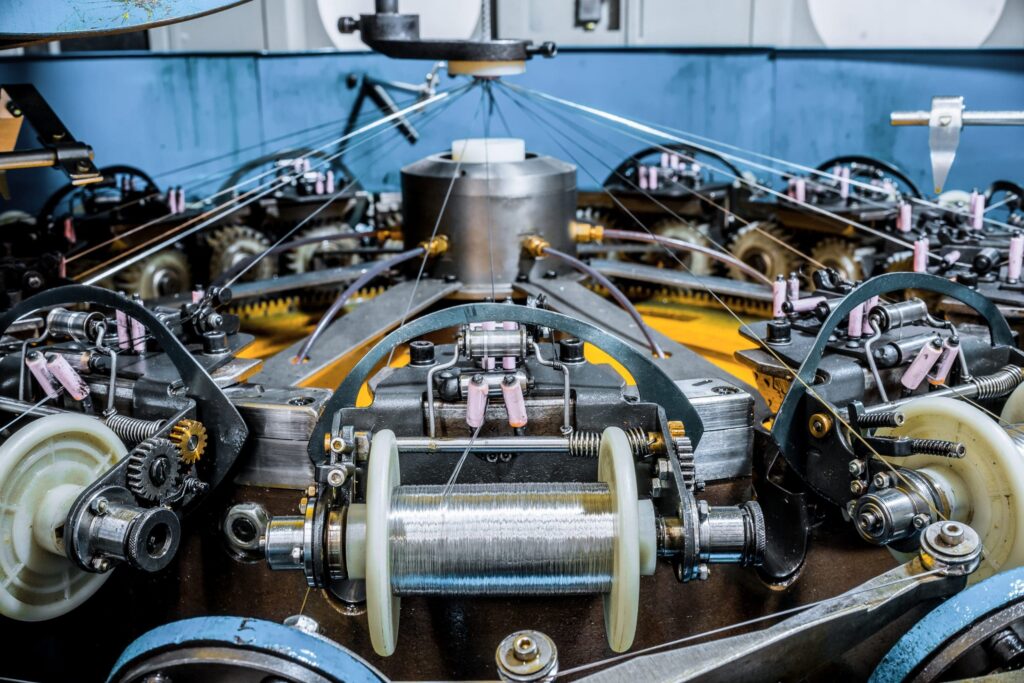

On drilling rigs—both onshore and offshore—slip rings are used in top drives, pipe handling systems, and rotary tables. These components continuously rotate, but still require electrical power and signal transmission to operate control valves, sensors, torque monitoring systems, and instrumentation. The slip ring allows for uninterrupted electrical connection between the rotating and stationary parts of the system.

Pharmaceutical and Chemical Mixing

In reactors or mixers used for pharmaceutical and chemical production, the vessels are often equipped with rotating agitators or blades. These require ongoing electrical power and control for temperature sensors, motor feedback, or batch control signals. Hazardous location slip rings allow the system to transmit this data continuously while rotating.

Mining Operations

In mining environments, slip rings are used in rotating equipment such as drill rigs, ventilation systems, conveyors, and excavation machines (e.g., continuous miners or bucket wheel excavators). These systems require continuous transmission of power, signals, and control data to rotating platforms that support cutting heads, winches, or sensor arrays. ROTOCON hazardous location slip rings eliminate the need for hanging cable loops or complex cable management systems, enabling safer and more reliable rotary motion.

EXPLORE MORE

Related Articles for Hazardous Location Slip Rings

Resources

Helpful Information

Get the details you need—explore our complete resource library on every slip ring series.