OVERVIEW

High Current Brushless Rotating Electrical Connectors for Reliable Power & Data Transfer

- Capable of transferring high currents up to 35 amps per channel / conductor

- Combine power and data in one assembly

- Highly configurable to specific applications needs

ROTOCON brushless high current slip rings are designed to mount at the end of a workpiece. The ROTOCON MY/MZ Series features a higher ampacity rating and channel count for high current or high channel count uses. For applications with less than 30 channels / contacts or less than 20 amps per contact, we recommend our ROTOCON MX-Series.

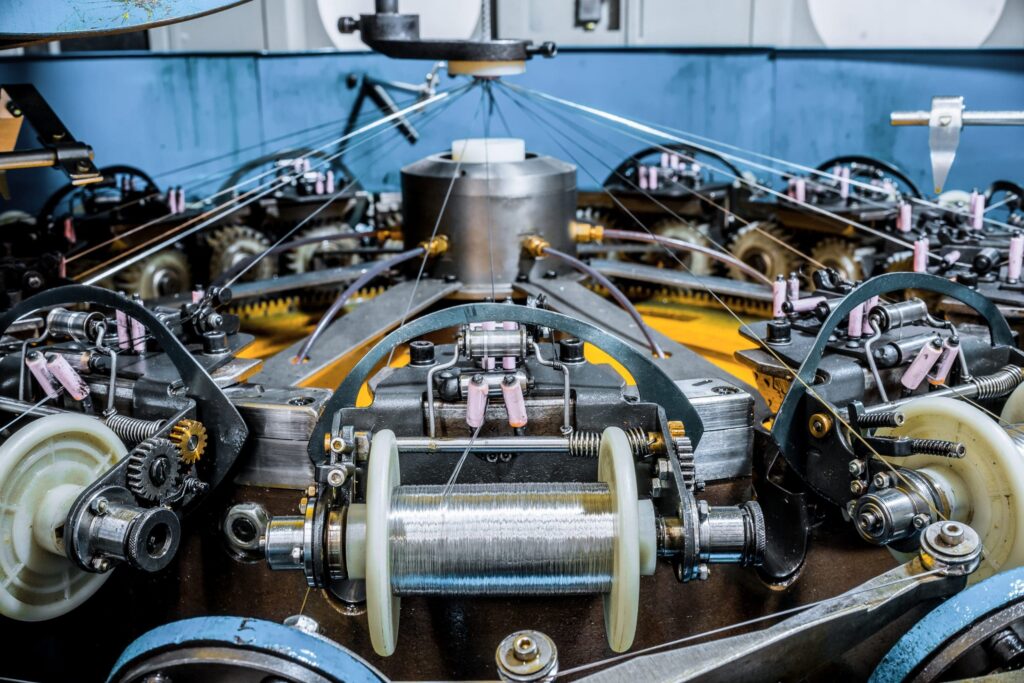

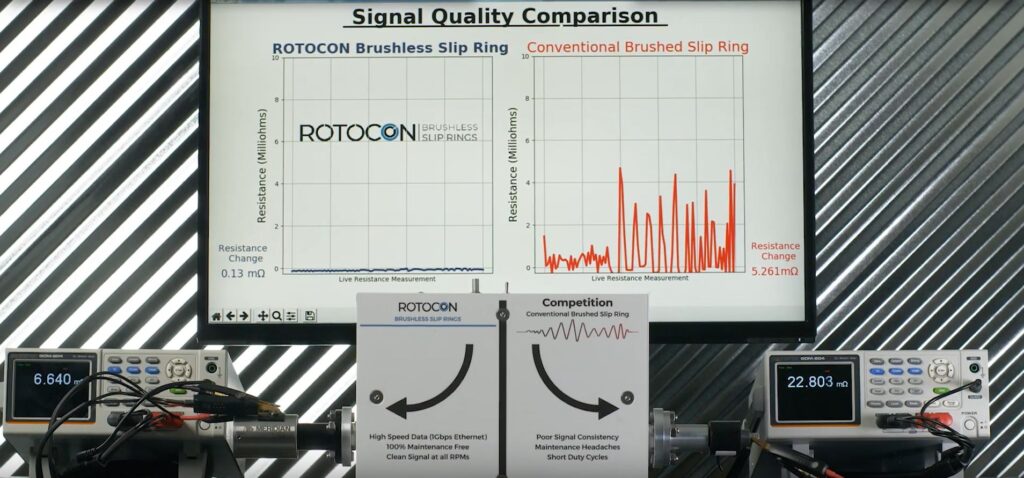

ROTOCON brushless high current slip rings are often used in thermoforming, packaging, water treatment, centrifuge, and many other industrial and scientific applications. They provide a maintenance-free and stable rotating electrical contact for high channel count and higher current applications. They provide clean electrical power and signal with no measurable electrical noise, and remain unaffected by machine vibration, rotational speed, and total number of revolutions.

All ROTOCON brushless high current slip rings are environmentally sealed and constructed with durable materials, making them the perfect solution for manufacturing, R&D, and other high-performance applications. Their rugged industrially-oriented design ensures dependable, long-lasting performance, eliminating the downtime and frequent maintenance typically required by traditional brushed slip rings.

ROTOCON brushless high current slip rings are highly configurable to suit the specific requirements of your application. Available options include mechanical mounting, electrical terminations, and other value-added features. Furthermore, Meridian Laboratory provides cost-effective and efficient solutions for Custom ROTOCON Slip Rings, accommodating both prototype and production quantity volumes.

Advantages

Why choose ROTOCON High Current Slip Rings?

READY TO ELEVATE YOUR EXPERIENCE?

Explore the possibilities and configure your ideal solution with Rotocon's Product Configurator. Tailor your product to your unique needs in just a few clicks!

CONFIGURE YOUR ROTOCON

Applications & Uses

Common Uses for High Current Slip Rings

CPG Processing & Packaging

CPG Processing & Packaging

P: ROTOCON high current slip rings are used for heated rollers and other general I/O signals in production and packaging equipment. They remain unaffected by changes in humidity, contact with liquids, and other environmental conditions.

Testing & Validation

ROTOCON high current slip rings are used in automotive dynamometer and centrifuge testing facilities providing a high channel count rotary connection of up to 60 contacts for signals and power to be transferred simultaneously.

Industrial Machinery & Equipment

ROTOCON high current slip rings are commonly used in wastewater treatment facilities, battery production lines, semiconductor equipment and many other applications which demand a reliable and long lasting slip ring connection for high current use.

EXPLORE MORE

Related Articles for High Current Slip Rings

Resources

Helpful Information

Get the details you need—explore our complete resource library on every slip ring series.