OVERVIEW

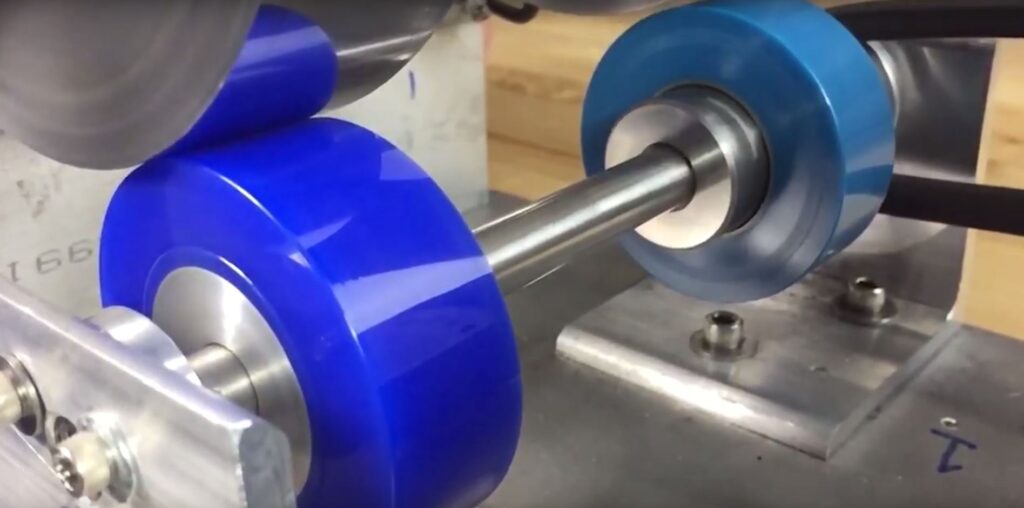

Polyurethane Coated Bearings

- Manufactured using high-quality, radial ball bearings.

- Precision molded for tight tolerances and low runout, ensuring smooth, consistent rotation.

- Provides surface protection, noise reduction, and enhanced traction in high-speed and high-cycle environments.

- ML6 polyurethane is bonded directly to the bearing OD with unmatched strength and durability.

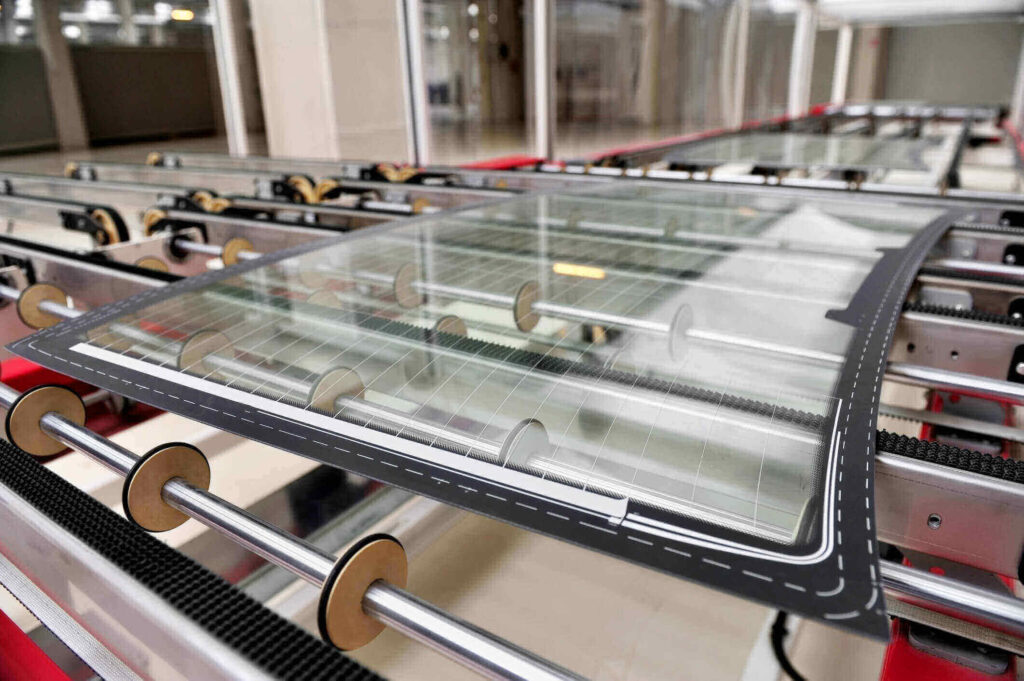

Polyurethane covered bearings are designed to provide reliable rotational motion while offering the added benefits of surface protection, vibration dampening, and improved longevity. They are ideal for applications involving conveyors, guiding systems, and automated machinery where non-marring contact and precise movement are required. Bearings can be directly molded to or be press-fit into housings depending on the system configuration and preference.

ML6 polyurethane molded bearings are used across a wide range of automation, converting, and industrial applications. They are available in multiple durometers, sizes, and polyurethane thicknesses to meet specific material handling, speed, and load requirements.

Standard ML6 polyurethane covered bearings are manufactured using high-quality sealed radial ball bearings, with stainless steel options available upon request. Both SAE and Metric sizes are offered, with standard bearing sizes.

Custom ML6 polyurethane bearings can be provided with specific bearing types, dimensions, specialized profiles, or application-specific formulas. Meridian Laboratory offers fast turnaround times and cost-effective solutions whether you need a one-off or a high-volume production run. [Click here to learn more about our custom ML6 polyurethane molding capabilities.]

All ML6 polyurethane coated bearings are manufactured using Meridian Laboratory’s proprietary ML6 formulas, bonded directly to the bearing’s outer diameter or to a precision machined core. This ensures excellent resistance to wear, impact, and tear-off—even under high-speed or continuous-duty conditions.

For molded polyurethane idler bushings, polyurethane covered cam followers, and polyurethane molded yoke rollers – click here for more information.

Meridian Laboratory’s precision molding process results in outstanding performance, low runout (TIR as low as 0.0015”), and a level of consistency unmatched by traditional over-molded or covered bearing options.

Learn more below about how Meridian Laboratory’s ML6 polyurethane covered bearings deliver superior reliability, performance, and service life across demanding industrial applications.

Advantages

Advantages of ML6 Polyurethane Covered Bearings

Specifications

Polyurethane Covered Bearing Models

| Name | Durometer | Outside Diameter | Roller Width | Bore Diameter | Bearing Type | Part Downloads | 2D Download Action Type | File Datasheet | Model Download (3D STP) |

|---|---|---|---|---|---|---|---|---|---|

| CBB-430-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.750" | 0.196" | 0.1875" | R3-2RS | Standard Models | MERIDIAN-LABORATORY-ML6-CBB-430-XXX.pdf | Yes | |

| CBB-440-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 1.000" | 0.281" | 0.250" | R4A-2RS | Standard Models | MERIDIAN-LABORATORY-ML6-CBB-440-XXX.pdf | Yes | |

| CBB-450-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 1.125" | 0.281" | 0.375" | R6-2RS | Standard Models | MERIDIAN-LABORATORY-ML6-CBB-450-XXX.pdf | Yes | |

| CBB-455-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 1.500" | 0.313" | 0.500" | R8-2RS | Standard Models | MERIDIAN-LABORATORY-ML6-CBB-455-XXX.pdf | Yes | |

| CBB-460-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 1.625" | 0.343" | 0.625" | R10-2RS | Standard Models | MERIDIAN-LABORATORY-ML6-CBB-460-XXX.pdf | Yes | |

| CBB-470-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 1.875" | 0.4375" | 0.750" | R12-2RS | Standard Models | MERIDIAN-LABORATORY-ML6-CBB-470-XXX.pdf | Yes | |

| CBB-480-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 2.500" | 0.500" | 1.250" | R20-2RS | Standard Models | MERIDIAN-LABORATORY-ML6-CBB-480-XXX.pdf | Yes | |

| Custom Polyurethane Covered Bearings | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 1/4" to 17" Outside Diameter | Wide variety of SAE & Metric sizes available | Wide variety of SAE & Metric sizes available | Wide variety of SAE & Metric sizes available |

Cost Effective Customization

Custom Molded Polyurethane – From Prototype to Production

Meridian Laboratory’s proven process for manufacturing custom Polyurethane Coated Bearings makes it easy and efficient to specify, order, and scale your polyurethane needs—no matter the volume.

Our unique manufacturing method is engineered for flexibility, allowing customers to go from prototype to full-scale production without costly tooling, long lead times, or complex ordering processes.

Why Engineers and Buyers Prefer Meridian Laboratory:

- Fast and Simple Quotation Process

Submit your dimensions, durometer, and application requirements—we work with you to ask the right questions, answer yours, and provide a solution. - Low Minimums, High Flexibility

Ideal for both one-off prototypes and full production runs without changing your process or supplier. - No or Low Setup Fees

Our streamlined approach eliminates traditional barriers like expensive molds or long production setups. - Scalable Without Disruption

As your demand grows, our polyurethane manufacturing process seamlessly scales with you—no re-engineering required.

Whether you’re prototyping a new design or ramping up to high-volume production, Meridian Laboratory makes custom polyurethane manufacturing simple, fast, and reliable.

Design Your Perfect Polyurethane Part

Use our comprehensive configurator to find or design the perfect polyurethane part with ease!

FAQs

Common Polyurethane Covered Bearing Questions

What size mount do I need?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat

Is this RoHS/CE compliant?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat

What speed does this reach?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat

How do I mount this item?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat

APPLICATIONS & USES

Common Uses for Polyurethane Molded Bearings

ML6 polyurethane covered bearings are used in equipment that harvests potatoes, pulling them from the ground while simultaneously separating the dirt.

ML6 polyurethane covered bearings are used in the track systems for vertical greenhouses and farming.

ML6 polyurethane covered shafts help convey radioactive materials across them.

EXPLORE MORE

Related Articles for Polyurethane Coated Bearings

Where to Purchase ML6 Polyurethane Covered Bearings?

RESOURCES

Information At Your Fingertips

Get the details you need—explore our complete resource library on every polyurethane product.