Overview

Molded Polyurethane Products for Nuclear Applications

Nuclear

ML6 Polyurethane for Crucial Nuclear Applications

Meridian Laboratory’s ML6 polyurethane parts are used in nuclear applications like fuel rod handling, inspection vehicles, and radioactive material conveyance. Parts are molded precisely to fit fuel rods and other components for a secure and damage-free grip, and are designed to hold up in radioactive environments without degrading. High friction properties help inspection vehicles maintain traction, while exact tolerances guarantee a safe operation in these critical applications.

Application & Uses

Common Applications & Uses for Molded Polyurethane Products in Nuclear

Capabilities

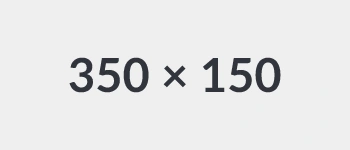

Engineering Capabilities & Services

Gallery

ML6 Molded Polyurethane for Nuclear Applications

Resources

Helpful Information

Browse our collection of slip ring resources to find detailed information on each model, including mounting instructions, applications, FAQs, whitepapers, and more.