Overview

Molded Polyurethane Products for Military & Defense Applications

Military & Defense

ML6 Parts for High-Stakes Military & Defense Uses

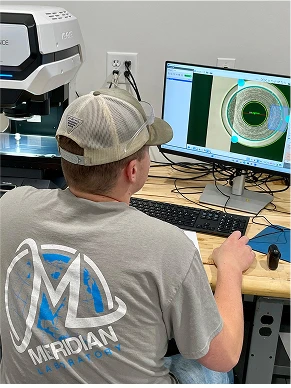

Meridian Laboratory’s ML6 polyurethane parts are trusted in high-stakes military applications including bomb diffusing robots, helicopter hoist tensioning, recoil buffers, grenade assembly, and precision media blasting. The high-friction ML6 material enables secure gripping and handling of delicate or dangerous components; custom-molded profiles fit exactly to application needs. Chemically bonded for superior durability, ML6 resists delamination and protects from wear during heavy use.

Application & Uses

Common Applications & Uses for Molded Polyurethane Products in Military & Defense

Capabilities

Engineering Capabilities & Services

Gallery

ML6 Molded Polyurethane for Military & Defence Applications

Resources

Helpful Information

Browse our collection of slip ring resources to find detailed information on each model, including mounting instructions, applications, FAQs, whitepapers, and more.