OVERVIEW

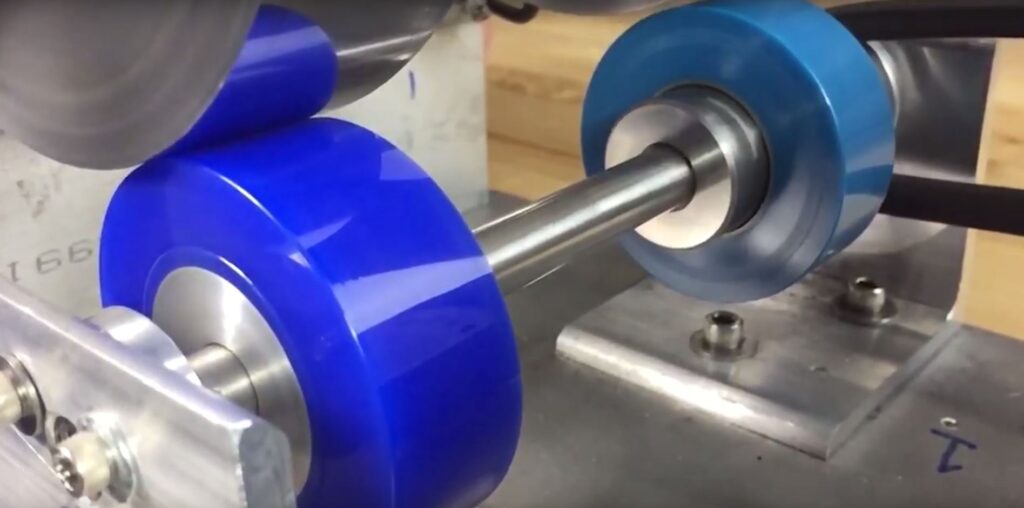

Low-Profile Polyurethane Molded Drive Rollers

- Low-profile design features the set screws going through the polyurethane to the bore, rather than being placed in an offset hub.

- Tight tolerances and low runout guaranteed with the precision molding process.

- High friction and durable ML6 polyurethane provides exceptional performance and longevity.

- Unbeatable bond strength between ML6 polyurethane and core materials.

Low-profile polyurethane molded drive rollers are designed to provide friction and drive materials with which they come into contact with. They are used in a wide range of industrial and automation applications where consistent motion transfer is required. ML6 low-profile drive rollers are available in a wide variety of different durometers, styles, sizes, and options.

Standard ML6 low-profile polyurethane molded drive rollers are supplied with set screws to mount to the shaft. The set screws go through the center of the hub, providing a lower profile roller for applications with limited space. Cores are typically made of 6061 aluminum, but are also available in a variety of metals, plastics, and other non-metallic materials as well.

Click here to see our complete lineup of polyurethane molded drive rollers.

Custom ML6 low-profile polyurethane molded drive rollers are available affordably, with quick turnaround times. Meridian Laboratory specializes in delivering high-quality, precision custom ML6 low-profile polyurethane molded drive rollers and wheels – ranging in quantities from 1 to 1M+. Click here to learn more about our custom ML6 polyurethane molding process.

All ML6 low-profile polyurethane molded drive rollers are manufactured with Meridian Laboratory’s ML6 polyurethane bonded directly to a center core, done so in a way that prevents tear-off and provides excellent longevity.

Meridian Laboratory’s process for molding precision ML6 low-profile drive roller technology ensures exceptional tolerances and total indicated runout as low as 0.0015”, far tighter than other manufacturers.

Learn more about all the advantages Meridian Laboratory’s ML6 polyurethane molding process delivers below!

Advantages

Advantages of ML6 Low-Profile Polyurethane Molded Drive Rollers

Specifications

Low-Profile Polyurethane Molded Drive Roller Models

| Name | Durometer | Outside Diameter | Roller Width | Bore Diameter | Set Screws | Part Downloads | 2D Download Action Type | File Datasheet | Model Download (3D STP) |

|---|---|---|---|---|---|---|---|---|---|

| AL-820-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.375" | 0.250" | 0.125" | 4-40 (1x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-820-XXX.pdf | Yes | |

| AL-821-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.500" | 0.250" | 0.1875" | 6-32 (1x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-821-XXX.pdf | Yes | |

| AL-822-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.500" | 0.250" | 0.250" | 6-32 (1x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-822-XXX.pdf | Yes | |

| AL-823-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.500" | 0.375" | 0.1875" | 6-32 (1x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-823-XXX.pdf | Yes | |

| AL-824-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.500" | 0.375" | 0.250" | 6-32 (1x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-824-XXX.pdf | Yes | |

| AL-825-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.500" | 0.500" | 0.1875" | 6-32 (1x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-825-XXX.pdf | Yes | |

| AL-826-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.500" | 0.500" | 0.250" | 6-32 (1x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-826-XXX.pdf | Yes | |

| AL-827-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.625" | 0.250" | 0.1875" | 6-32 (1x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-827-XXX.pdf | Yes | |

| AL-828-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.625" | 0.250" | 0.250" | 6-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-828-XXX.pdf | Yes | |

| AL-830-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.625" | 0.375" | 0.1875" | 6-32 (1x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-830-XXX.pdf | Yes | |

| AL-831-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.625" | 0.375" | 0.250" | 6-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-831-XXX.pdf | Yes | |

| AL-832-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.625" | 0.500" | 0.1875" | 6-32 (1x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-832-XXX.pdf | Yes | |

| AL-833-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.625" | 0.500" | 0.250" | 6-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-833-XXX.pdf | Yes | |

| AL-834-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.625" | 0.625" | 0.1875" | 6-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-834-XXX.pdf | Yes | |

| AL-835-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.625" | 0.625" | 0.250" | 6-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-835-XXX.pdf | Yes | |

| AL-836-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.750" | 0.375" | 0.250" | 6-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-836-XXX.pdf | Yes | |

| AL-837-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.750" | 0.500" | 0.250" | 6-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-837-XXX.pdf | Yes | |

| AL-838-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.750" | 0.625" | 0.250" | 6-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-838-XXX.pdf | Yes | |

| AL-840-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 0.750" | 0.750" | 0.250" | 6-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-840-XXX.pdf | Yes | |

| AL-841-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 1.000" | 0.250" | 0.250" | 6-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-841-XXX.pdf | Yes | |

| AL-842-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 1.000" | 0.500" | 0.250" | 8-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-842-XXX.pdf | Yes | |

| AL-843-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 1.250" | 0.250" | 0.3125" | 6-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-843-XXX.pdf | Yes | |

| AL-844-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 1.250" | 0.750" | 0.3125" | 8-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-844-XXX.pdf | Yes | |

| AL-845-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 1.625" | 0.250" | 0.375" | 8-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-845-XXX.pdf | Yes | |

| AL-846-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 1.625" | 0.750" | 0.375" | 10-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-846-XXX.pdf | Yes | |

| AL-847-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 2.000" | 0.250" | 0.375" | 8-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-847-XXX.pdf | Yes | |

| AL-848-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 2.000" | 0.750" | 0.375" | 10-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-848-XXX.pdf | Yes | |

| AL-850-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 2.500" | 0.375" | 0.500" | 10-32 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-850-XXX.pdf | Yes | |

| AL-851-XXX | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 2.500" | 1.000" | 0.500" | 1/4"-28 (2x) | Standard Models | MERIDIAN-LABORATORY-ML6-AL-851-XXX.pdf | Yes | |

| Custom Hubless Polyurethane Drive Roller | 40A | 55A | 70A | 80A | 90A | 60D | 75D | 3/8" to 17" Outside Diameter | Up to 28" Long | 1/32" to 16" Bore Diameter | Customizable to Specifications |

Cost Effective Customization

Custom Molded Polyurethane – From Prototype to Production

Meridian Laboratory’s proven process for manufacturing custom Low-Profile Polyurethane Molded Drive Rollers makes it easy and efficient to specify, order, and scale your polyurethane needs—no matter the volume.

Our unique manufacturing method is engineered for flexibility, allowing customers to go from prototype to full-scale production without costly tooling, long lead times, or complex ordering processes.

Why Engineers and Buyers Prefer Meridian Laboratory:

- Fast and Simple Quotation Process

Submit your dimensions, durometer, and application requirements—we work with you to ask the right questions, answer yours, and provide a solution. - Low Minimums, High Flexibility

Ideal for both one-off prototypes and full production runs without changing your process or supplier. - No or Low Setup Fees

Our streamlined approach eliminates traditional barriers like expensive molds or long production setups. - Scalable Without Disruption

As your demand grows, our polyurethane manufacturing process seamlessly scales with you—no re-engineering required.

Whether you’re prototyping a new design or ramping up to high-volume production, Meridian Laboratory makes custom polyurethane manufacturing simple, fast, and reliable.

Design Your Perfect Polyurethane Part

Use our comprehensive configurator to find or design the perfect polyurethane part with ease!

FAQs

Common Low-Profile Polyurethane Molded Drive Roller Questions

What size mount do I need?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat

Is this RoHS/CE compliant?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat

What speed does this reach?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat

How do I mount this item?

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat

APPLICATIONS & USES

Common Uses for Low-Profile Polyurethane Molded Drive Rollers

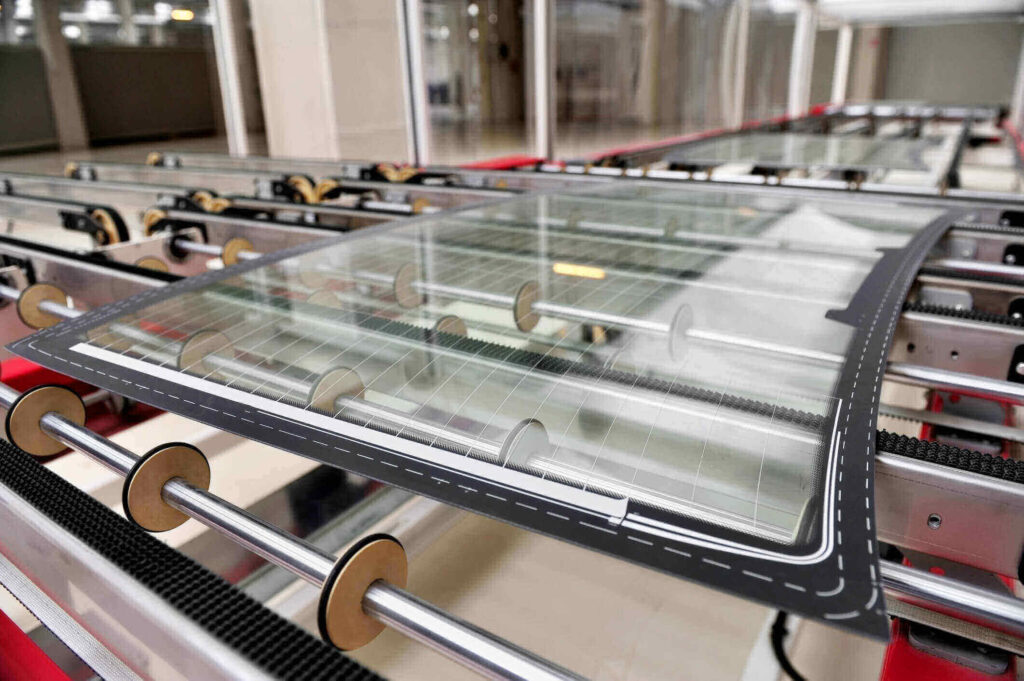

Label Application

ML6 polyurethane covered rollers and shafts are commonly used to apply labels onto packages, bottles, and other products.

Wire Feed, Strip, and Cut

ML6 polyurethane drive rollers are used by many of the world’s leading manufacturers of wire processing equipment for feeding, stripping, and assembly of difficult-to-process wires such as Teflon.

Automated Packaging

ML6 polyurethane covered drive rollers and grippers are used in automated equipment for a wide array of packaging and assembly applications.

Industries

Industries that use ML6 Low-Profile Polyurethane Molded Drive Rollers

EXPLORE MORE

Related Articles for Low-Profile Polyurethane Molded Drive Rollers

Where to Purchase ML6 Low-Profile Polyurethane Molded Drive Rollers?

RESOURCES

Information At Your Fingertips

Get the details you need—explore our complete resource library on every polyurethane product.