Overview

Molded Polyurethane Products for Fitness Applications

Fitness

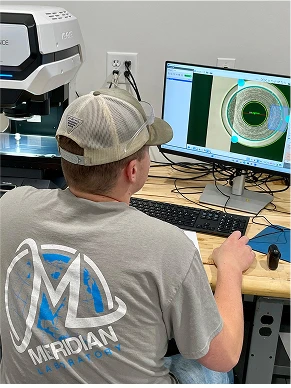

ML6 Bearing Assemblies for Fitness Equipment Performance

Meridian Laboratory’s ML6 polyurethane bearings, idler wheels, and bumpers are utilized in fitness equipment like pilates reformers, elliptical machines, and playground monorail gliders. Our unique bonding process keeps the polyurethane firmly attached to the metal core, even after endless back-and-forth sliding and repeated use. ML6 parts are molded precisely to match the tracks they ride on and move smoothly for a quiet operation; no rattling, clunking, or uneven movement. They even withstand outdoor conditions including rain, snow, temperature fluctuations, and will last for the long term.

Application & Uses

Common Applications & Uses for Molded Polyurethane Products in Fitness

Capabilities

Engineering Capabilities & Services

Gallery

ML6 Molded Polyurethane for Fitness Applications

Resources

Helpful Information

Browse our collection of slip ring resources to find detailed information on each model, including mounting instructions, applications, FAQs, whitepapers, and more.