Overview

Molded Polyurethane Products for Automotive & Transportation Applications

Automotive & Transportation

ML6 Components for Automotive & Transportation Uses

Meridian Laboratory’s ML6 polyurethane parts are found in several automotive and transportation uses, such as robotic chassis assembly, mobility vehicle lift gates, action sports camera mounts, and heavy-duty vehicle lifts. They grip freshly painted surfaces without leaving marks. The durability can be attributed to the strong bond strength of ML6 polyurethane that won’t peel or delaminate. Since these parts endure heavy use, they are made to resist wear, flat spots, and harsh exposure like road salt and grime.

Application & Uses

Common Applications & Uses for Molded Polyurethane Products in Automotive & Transportation

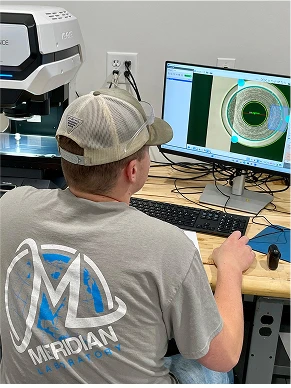

Capabilities

Engineering Capabilities & Services

Gallery

ML6 Molded Polyurethane for Automotive & Transportation Applications

Resources

Helpful Information

Browse our collection of slip ring resources to find detailed information on each model, including mounting instructions, applications, FAQs, whitepapers, and more.